Search Products by:

WELCOME TO DRIVE-LINE

Drive-Line Inc. Your Trusted Industrial Brake and Clutch Supplier

Over the past 50 years, Drive-Line, Inc. has become a leading expert for the supply and service of all industrial clutch and brake requirements across a wide range of Canadian markets. We have partnered with some of the leading manufacturers to deliver the most advanced solutions available on today’s market.

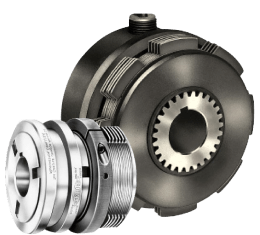

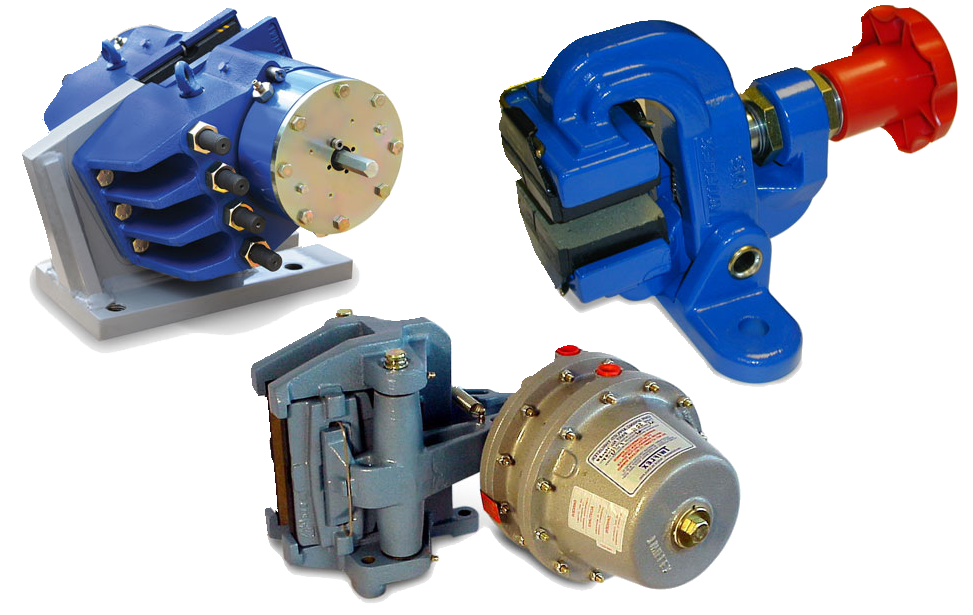

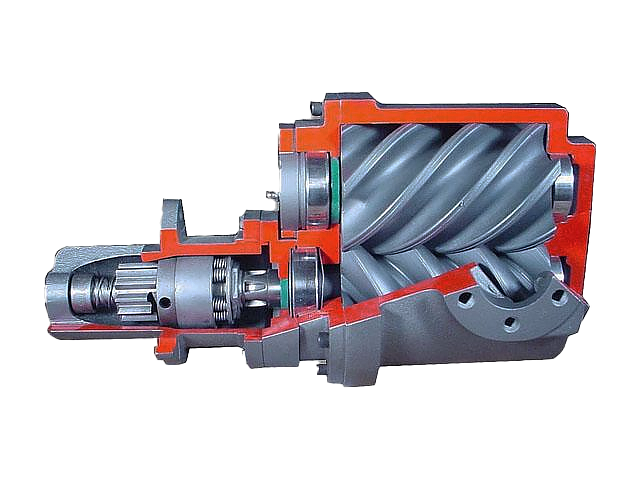

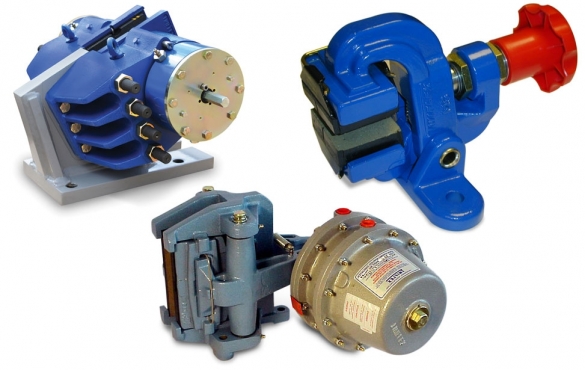

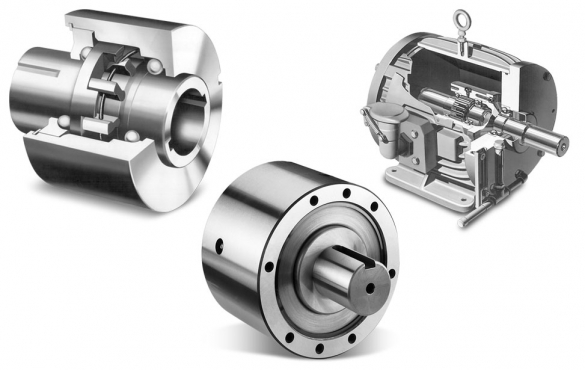

Drive-Line Inc.'s manufacturing partnerships feature industrial brakes and clutches from recognized brands like Twiflex, Hilliard, Goizper, and Carlyle-Johnson. Our key product lines include:

- Hydraulic and pneumatic clutch/brake systems

- Calipers and modular brakes

- Ball bearing and sprag-type freewheel clutches

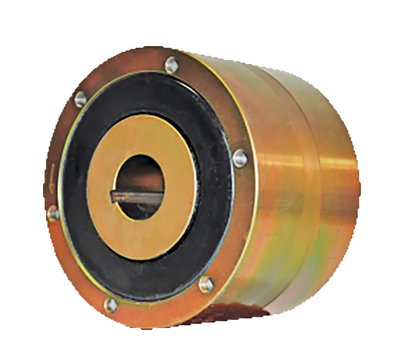

- Various types of tension control clutches and brakes

- Overrunning and single revolution clutches

- Single and multi disc electromagnetic and mechanical brakes.

Please browse through our Product Categories to find the motion control solutions you need. Our selection is continuously updated as new items become available. We stock a wide variety of products to provide quick delivery times throughout Canada.

MANUFACTURERS WE REPRESENT

Drive Line Inc. has partnered with manufacturers who share our commitment to provide high quality and reliability for our customers. You can browse by product categories or available brands.

Disc Brake Systems

Disc Brake Systems

Hydraulic Brakes

Hydraulic Brakes

Oil Immersed Clutches and Brakes

Oil Immersed Clutches and Brakes

Spare Parts

Spare Parts

Special Purpose Products

Special Purpose Products

Mechanical Friction Torque Limiter

Mechanical Friction Torque Limiter

Pneumatic Clutches

Pneumatic Clutches

Brake Pads

Brake Pads

Hydraulic Power Units

Hydraulic Power Units

Braking Controls

Braking Controls

Brake Disc

Brake Disc