Air Engaged Brakes

SPRING AND AIR ENGAGED FRICTION BRAKES

Pneumatic friction brakes from Mach III provide simple solutions for stopping and holding.

Spring engaged brakes remain engaged in the absence of air pressure. They are often referred to as power-off brakes, fail-safe brakes or holding brakes. These brakes are best suited for applications where they are used to prevent rotary motion of a load and are not suitable for dynamic stopping.

Air engaged brakes are applied with compressed air and release in the absence of air pressure. They are often referred to as power-on brakes. These brakes are best suited for bringing a load to a stop and preventing rotary motion of a load.

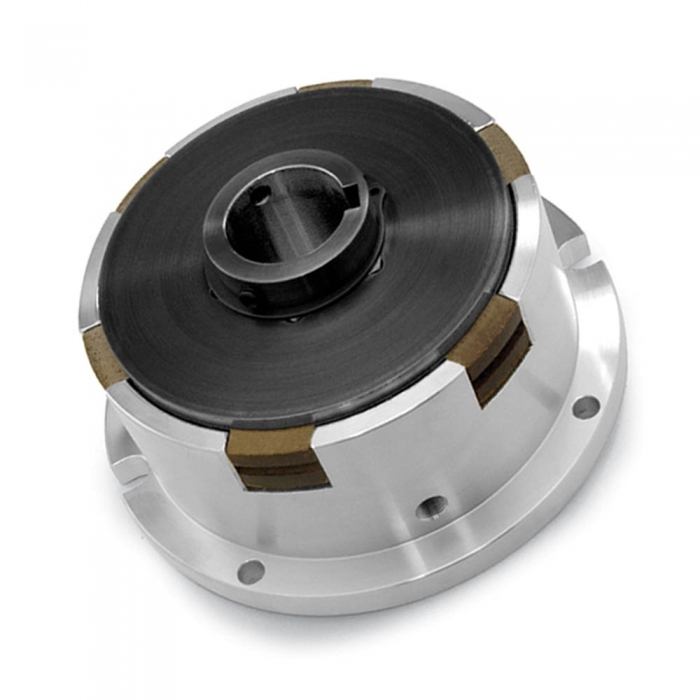

AIR ENGAGED BRAKES

Flange Mounted Friction Brakes For Stopping and Holding

Function: Stopping, Holding (Cycling Applications)

Drive Arrangement: Machine Frame or Bracket to Shaft

- Applying air pressure compresses drive and friction discs to produce torque.

- Torque is proportional to the air pressure applied.

- Separator springs assure full brake release when air pressure is absent.

Operation

Air pressure compresses drive and friction discs to produce torque.

Torque is linear in response to the air pressure applied.

Release springs provide positive disengagement when air is exhausted.

Mounting

The brake flange bolts to a machine frame or other fixture, the shaft inserts into the bore and is fixed with a customer supplied key.

Can also be mounted mid-shaft with the flange connected to a bracket.

Air engaged friction brakes are designed for horizontal mounting. If vertical mounting is required, consult engineering.

Applications

Air engaged friction brakes are suitable for stopping, holding and cycling applications.

Maximum RPM varies by model and is listed on the PDF detail sheet (see table below). Consult engineering if the intended application exceeds the listed maximum RPM.

Design Features

Air engaged brakes are made-to-order with any bore size up to the maximum shown for easy installation.

Drilled and slotted flange allows for variable installation arrangements.

Low coefficient friction lining versions are available for applications requiring slip or a narrower torque range. Contact engineering for details.

|

Product Code |

Torque @ 80 PSI |

Maximum Bore with Standard Keyway |

Detail Sheet |

|

B2F2R-STH |

100 lb-in |

0.500 in (12 mm) |

|

|

B3F2R-STH |

267 lb-in |

1.000 in (24 mm) |

|

|

B4F2R-STH |

760 lb-in |

1.250 in (31 mm) |

|

|

B5F2R-STH |

1,584 lb-in |

1.438 in (38 mm) |

|

|

B6F2G-STH |

3,118 lb-in |

2.000 in (52 mm) |

|

|

B8F2K-STH |

4,788 lb-in |

2.375 in (66 mm) |

|

|

BAF2K-STH |

9,673 lb-in |

2.750 in (72 mm) |

Quote Request

If you have any questions regarding the products we are offering, pleasee fill out the form below and one of our representavies will contact your shortly. Thank you for your interest in Drive Line!