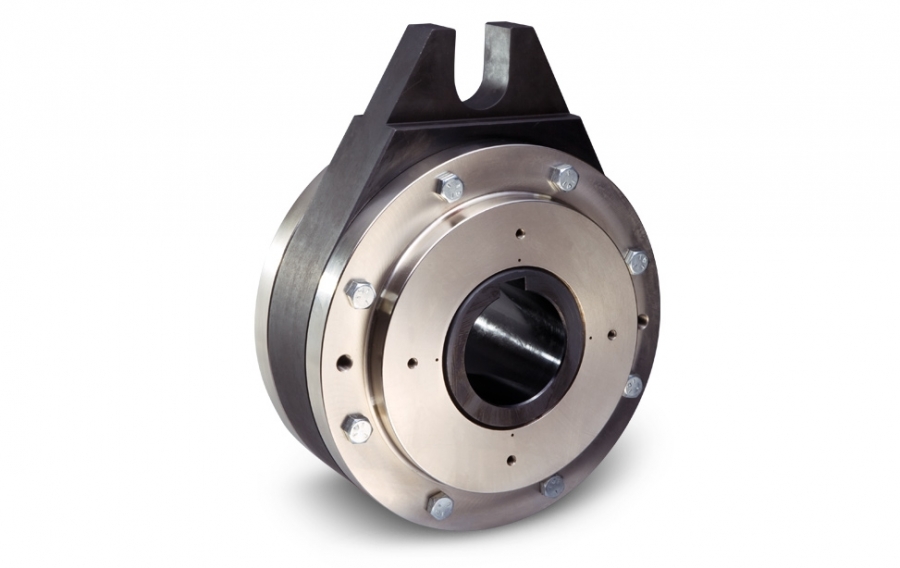

FHB Backstopping Clutch

Model FHB is a high speed, centrifugal throw-out (C/T) Sprag type backstop with internal sealed ball bearings. This self-contained design is completely maintenance free. It requires no re-lubrication, no external control, and no adjustment. It engages instantaneously and automatically to prevent any reverse shaft rotation. Model FHB operates at higher overrunning speeds and holds greater torque loads than competing backstops. A larger number of torque transmitting C/T Sprags reduce the hertzian contact stresses during backstopping leading to longer life than is possible with shoe designs.

The FHB backstop is mounted on a through-shaft with its inner race driven by a key, and its integral outer race torque arm prevented from rotating through a clearance fit interface with a fixed reaction pin. The reaction pin may also be used to provide axial restraint of the backstop on the rotating shaft. Typical uses for the Model FHB backstop include inclined conveyors, bucket elevators, and other applications where a rotating shaft must be absolutely prevented from rotating in a reverse direction, as commonly found in mining, aggregates, material handling, and other industries. The high speed capability of the unit make this backstop ideal for mounting on double extended input shafts of gear reducers. The overrunning speed of the rotating shaft should be greater than 400 RPM to assure C/T Sprag “lift-off”.

- Model FHB is directly interchangeable with the older FALK® Model BIF external high-speed backstop.

- Shipped from the factory lubricated for life

- Ambient operating temperatures range is from -40°F (-40°C) to 150°F (65°C).

Quote Request

If you have any questions regarding the products we are offering, pleasee fill out the form below and one of our representavies will contact your shortly. Thank you for your interest in Drive Line!