KEVO

For the actuation of auxiliary power generating sets in vehicles, general mechanical engineering

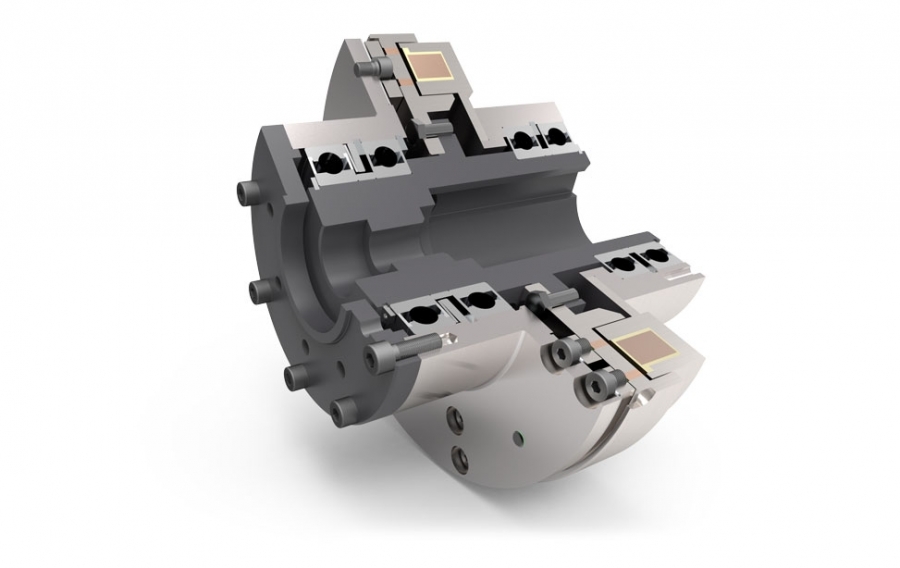

Electromagnetically connected Pole-Face Friction Clutch for a clean, simple control

Improved integration of various drive systems in drive trains (hybrid technology) and development of low-consumption drives require various units to be connected and disconnected. This requires clutches with a low consumption, very good space-torque ratio and disconnection almost free from residual torque.

Application

Actuation of auxiliary power generating sets in agriculture machinery, municipal vehicles, and textile machines or compressor drives for cooling units, laundry machines, proof systems and PTO-drives.

Benefits

- Torque from 7 Nm to 7800 Nm

- Electromagnetically operated for a clean, simple actuation

- 4-pole technology for high power density

- Small dimensions

- High switching frequency allowed

- Short switching times

- Fixed and wear-free power transmission without a slip ring

- Diaphragm technology allows for torque transmission free from backlash and disconnecting free from residual torque

- Low idling torque

- Low axial restoring power thanks to diaphragm

- Steel-steel friction combination, hardened for high wear resistance

- Coil body with coil: thermal class 155

- Diaphragm: for low axial restoring forces

- Anchor plate: positive heat dissipation thanks to ventilation effect

- Special surface protection: nitrocarburized

- Rotor/anchor plate: Steel-steel friction combination, Hardened for high wear resistance

- Electrical connection: 2-pole plug or flying leads

Quote Request

If you have any questions regarding the products we are offering, pleasee fill out the form below and one of our representavies will contact your shortly. Thank you for your interest in Drive Line!