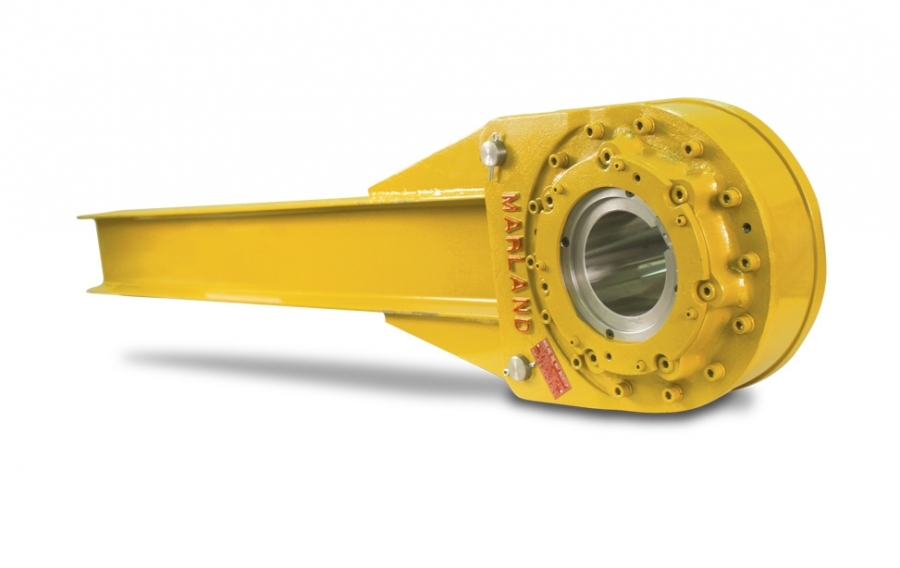

BC Model Backstop

These extremely reliable roller style, bearing supported backstops provide positive protection against potentially dangerous and damaging reverse torque runaways of inclined conveyors. Units are designed to be installed on the low-speed side of the conveyor’s head shaft drive -- where reverse torque loads originate.

Self-contained, oil-lubricated BC models are built to operate in dusty, high temperature mine and quarry environments. All units feature a grease labyrinth seal that prevents dust from attacking internal oil lip seals that could wear and leak if infiltrated.

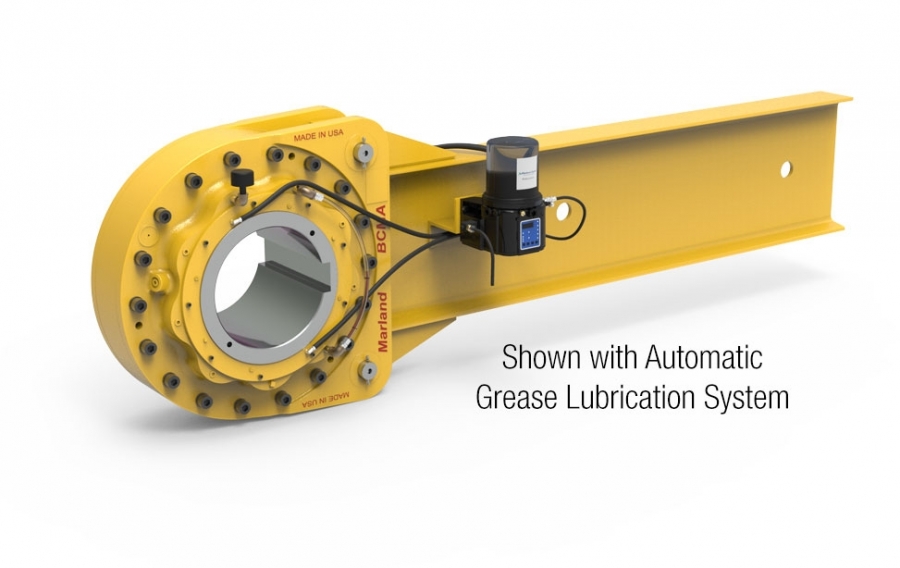

Marland’s new optional BCMA Backstop Automatic Grease Lubrication System provides protection from external contamination while eliminating the need to manually grease the labyrinth seals. The automatic system is designed to perform regularly scheduled injections of the proper volume of grease into the labyrinth seal to maintain a fresh grease barrier.

The new Smart Marland Monitoring System is an available option that provides up-to-the-minute remote access to critical backstop operating conditions including vibration, temperature and oil level, from anywhere using a computer or cell phone.

- 19 standard models available with torque ranges up to 2,100,000 lb.ft.

- Superior roller design

- Lower stresses

- Full contact Taconite seals

- Positive triple-sealing

- Removable torque arm

- 20-year, 24/7/365 service life

- Global product support

- Optional Automatic Grease Lubrication System

- Optional Smart Marland Monitoring System

Quote Request

If you have any questions regarding the products we are offering, pleasee fill out the form below and one of our representavies will contact your shortly. Thank you for your interest in Drive Line!